Environmentally friendly. Economical. Safe.

Ozone

in technical application

What is ozone?

Unlike atmospheric oxygen, which consists of only two atoms, ozone is a molecule of three oxygen atoms.

How is ozone formed?

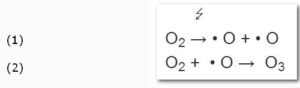

Ozone is formed in nature during discharge by lightning. This phenomenon is recreated in the Kaufmann ozone modules. Ozone is generated from oxygen in the modules in a high-voltage field by means of a silent electrical charge. The oxygen molecule is split by the technically generated lightning (1) and can combine with a free oxygen molecule as a free radical (2).

Atmospheric air consists of 78% nitrogen, 21% oxygen, and carbon dioxide and noble gases.

KUT Ozone generation plants

Due to its instability, ozone must be generated directly on site.

Ozone production requires only electrical energy and oxygen. The excess ozone decomposes back to oxygen and thus ozone production can rightly be called environmentally friendly and green chemistry.

Ozone generation plants from KUT operate in a vacuum with ambient air. As a pressurized system with compressed air or with oxygen from O2 generators or technical oxygen (LOX).

KUT offers ozone generation plants in different sizes with different capacities - from 10 gO3/h - 12 kgO3/h. The modular design allows us to adapt optimally to your performance requirements.

Technical advantages

Highest operational safety due to individual fuse protection of the high-voltage electrodes. Failure of one electrode does not mean failure of an ozone module and the ozone system continues to run without interruption. The power is only reduced in the order of magnitude of the individual electrode.

In our designs, the glass tubes do not come into contact with cooling water. Creeping currents due to condensation on the glass tubes are thus excluded. By means of an economy circuit, the cooling water flow can be controlled depending on the cooling water temperature. This leads to a reduction in the cooling water requirement and thus to energy cost savings.

Increased operational safety through the use of vacuum technology. In order to prevent ozone escaping into the apparatus room in the event of a defect occurring in the system, the generators are operated in the vacuum range.

With the Siemens SIMATIC S7-1200 control system, we offer you state-of-the-art technology with process visualization and simple operation via touch screen.

Our plant technology allows the cooling water to be used for heat recovery.

The modular design allows compact multi-circuit systems to be implemented in standard control cabinets and flexible placement of the control cabinets for optimal space utilization (in smaller rooms).

Depending on the type of plant, uninterrupted operation during maintenance is possible.